Products

Special machine tool for coupling spray welding

Spray welding is to reheat the preheated autolytic alloy powder coating to 1000~1300°C to melt the particles and cause slagging to float to the surface of the coating.

Classification:

Special machine tool for hoop spray welding

Key words:

Special machine tool for coupling spray welding

Product Description

Spray welding is to reheat the preheated autolytic alloy powder coating to 1000~1300°C to melt the particles and cause slagging to float to the surface of the coating. The generated boride and silicide are dispersed in the coating, causing the particles to Achieve good bonding with the substrate surface. The final deposit is a dense metal crystal structure and forms a metallurgical bonding layer with the matrix of about 0.05~0.1mm. Its bonding strength is about 400MPa. It has good impact resistance, wear resistance, corrosion resistance, and a mirror appearance.

Compared with the spray coating, the spray welding layer has significant advantages. However, due to the local heating of the matrix during the remelting process, the temperature reaches 900°C, which will cause large thermal deformation. Therefore, the scope of use of spray welding has certain limitations. Parts and materials suitable for spray welding are generally:

① Visible parts subject to impact loads require high surface hardness and good wear resistance, such as sandblasting machine blades, crusher tooth plates, excavator bucket teeth, etc.;

② Large wearing parts with relatively simple geometric shapes, such as shafts, plungers, sliders, hydraulic cylinders, chute plates, etc.;

③ Low carbon steel, medium carbon steel (carbon content less than 0.4%), structural steel containing manganese, molybdenum, vanadium total <3%, nickel-chromium stainless steel, cast iron and other materials.

Service Purpose

The pursuit of value is the starting point of our work, creating value is the driving force of our life, and realizing value is our constant pursuit! To provide customers with advanced automation products and technology, in accordance with the principle of customer first, mutual benefit, to provide perfect sales and technical services.

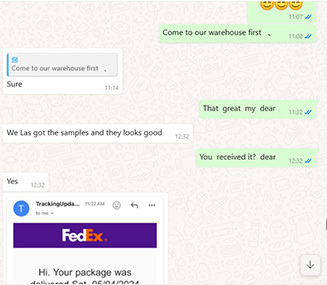

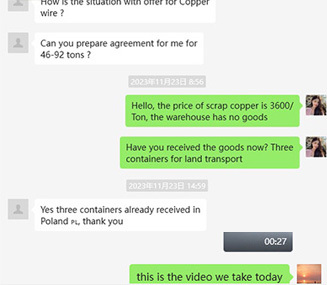

Customer Visits

Sincerely welcome all sectors to visit, inspect, and negotiate business. Our company will rely on scientific management, high team spirit, and the wisdom of all employees to take advantage of the booming development of Shandong and work together with all sectors of society to promote the progress and development of SEG automation control technology.

Customer Service

Qualification patent

Digging deep into customer resources is the foundation of our work, and cooperation and interaction are the process of our work; cost saving, profit maximization, quality service, and advancing with the times are the focus of our work, and win-win is the result of our pursuit

recommend products

Ultra-high frequency induction heating power supply equipment

Ultra high frequency induction heating equipment is widely used in fields such as metal processing

Ultrasonic induction heating equipment GCYP36

The ultrahigh frequency induction heating equipment uses IGBT modules

Ultrasonic induction heating equipment GCYP65

The ultrahigh frequency induction heating equipment uses IGBT modules

Ultrasonic series induction heating equipment

The ultra-audio induction heating equipment adopts IGBT module, which is energy-saving and power-saving: 30% power-saving compared with electronic tube type and 20% power-saving than controlled silicon intermediate frequency.

Welcome your message consultation

Our staff will contact you within 48 hours (working days), if you need other services, please call the service hotline