Products

The equipment produced by the company includes induction heating equipment and oil pipe and rod related petroleum equipment.

Ultra-high frequency induction heating power supply equipment

Ultra high frequency induction heating equipment is widely used in fields such as metal processing

Ultrasonic series induction heating equipment

The ultra-audio induction heating equipment adopts IGBT module, which is energy-saving and power-saving: 30% power-saving compared with electronic tube type and 20% power-saving than controlled silicon intermediate frequency.

MFP medium frequency induction heating equipment

Medium frequency induction heating equipment is widely used in heating occasions that require heat penetration.

DIHP series digital induction heating equipment

The medium frequency power supply series adopts parallel resonance in structure, adopts our company's fourth-generation inverter control technology in control, and uses IGBT as the main power device.

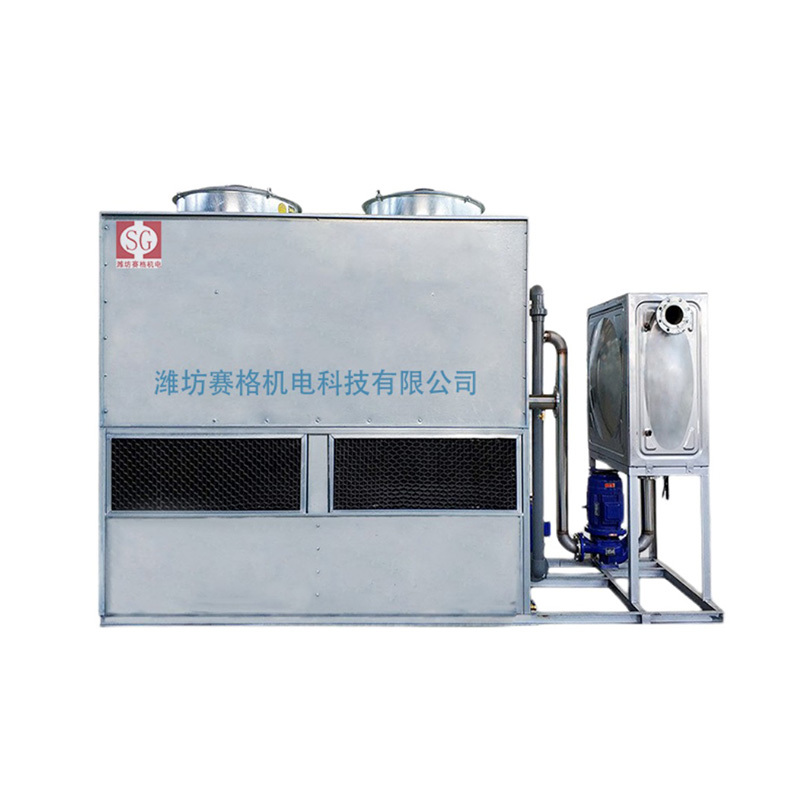

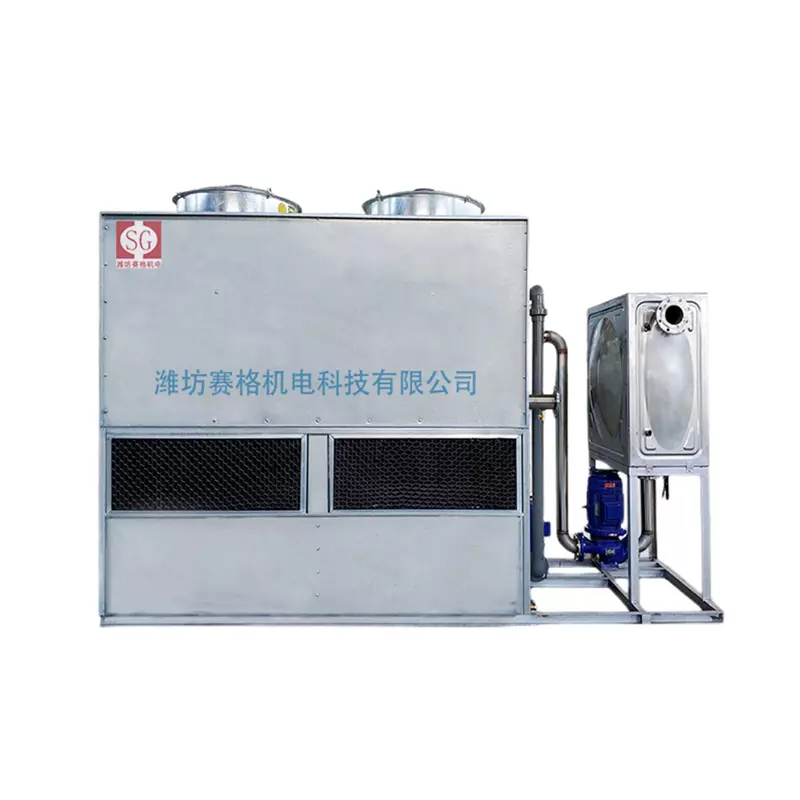

Closed-loop water cooling equipment

50T, 60T, 80T are equipped with dual pumps. If there are more than one cooling path, please indicate in advance. It can be customized.

The company was established in

Product Series

Registered capital

Cumulative Service Customers

Weifang Saige Electromechanical specializes in the production of induction heating power supply and its supporting equipment. It adheres to the guidelines of science and technology as the pioneer, quality as life, and service as the guarantee. It is deeply loved and unanimously praised by the majority of users. All colleagues of the company will make unremitting efforts to work with a pragmatic business style, excellent quality, perfect pre-sale consultation and after-sales service, and sincerely work together with the majority of customers to create the future together.

Pursue excellence endlessly, keep pace with the times and create the future! The pursuit of value is the starting point, the creation of value is the driving force, and the realization of value is the pursuit.

To provide customers with advanced automation products and technology, in accordance with the principle of customer first, mutual benefit, to provide perfect sales and technical services

ABOUT US

WEIFANG SAIGE ELECTROMECHANICAL TECHNOLOGY CO., LTD

Is a research and development, production, sales and service in one of the high-tech innovative enterprises.

The company's equipment includes induction heating equipment and oil pipe oil rod related oil equipment. Induction heating equipment includes ultra-audio induction heating series, high frequency, ultra-high frequency induction heating series, medium frequency induction heating series and supporting CNC quenching machine tools, closed cooling towers, etc. Products are widely used in automobile manufacturing, machine tool production, hardware and pipe processing, petroleum equipment production and other fields.

Company oil equipment production equipment includes: sucker pipe cleaning and repainting complete production line, sucker rod cleaning and repainting complete production line, coupling spray welding and remelting complete equipment, high molecular polyethylene lined oil pipe production complete equipment, titanium nano polymer coating anti-corrosion oil pipe production equipment, sucker rod forging rod head diathermy production line, sucker rod intermediate frequency quenching and tempering production line, sucker rod ultra-high molecular weight polymer coated anti-corrosion sucker rod head spray welding and remelting complete equipment, etc.

Advantage snow

Select SEG, Select Quality

Create value for users

Specializing in the production of induction heating power supply and its supporting equipment

Production capacity

Technical advantages

Sandardized system

Industry position

Service system

Production capacity

Technical advantages

Sandardized system

Industry position

Service system

News

2025-05-13

Recently, Weifang Saige Electromechanical Technology Co., Ltd. has achieved successful applications in multiple industry fields with its innovative "trinity" heat treatment system solution (induction heating + numerical control quenching + closed cooling). It has helped customers significantly reduce production costs and improve production efficiency, further consolidating the company's leading position in the field of heat treatment technology.

View Details2025-03-18

2025-02-25

2025-02-19