Products

Ultra-high frequency induction heating power supply equipment

Ultra high frequency induction heating equipment is widely used in fields such as metal processing

View DetailsUltrasonic induction heating equipment GCYP36

The ultrahigh frequency induction heating equipment uses IGBT modules

View DetailsUltrasonic induction heating equipment GCYP65

The ultrahigh frequency induction heating equipment uses IGBT modules

View DetailsUltrasonic series induction heating equipment

The ultra-audio induction heating equipment adopts IGBT module, which is energy-saving and power-saving: 30% power-saving compared with electronic tube type and 20% power-saving than controlled silicon intermediate frequency.

View DetailsUltrasonic induction heating equipment GCYP120

The ultrahigh frequency induction heating equipment uses IGBT modules

View DetailsUltrasonic induction heating equipment GCYP160

The ultrahigh frequency induction heating equipment uses IGBT modules

View DetailsUltrasonic induction heating equipment GCYP200

The ultrahigh frequency induction heating equipment uses IGBT modules

View DetailsMFP medium frequency induction heating equipment

Medium frequency induction heating equipment is widely used in heating occasions that require heat penetration.

View DetailsDIHP series digital induction heating equipment

The medium frequency power supply series adopts parallel resonance in structure, adopts our company's fourth-generation inverter control technology in control, and uses IGBT as the main power device.

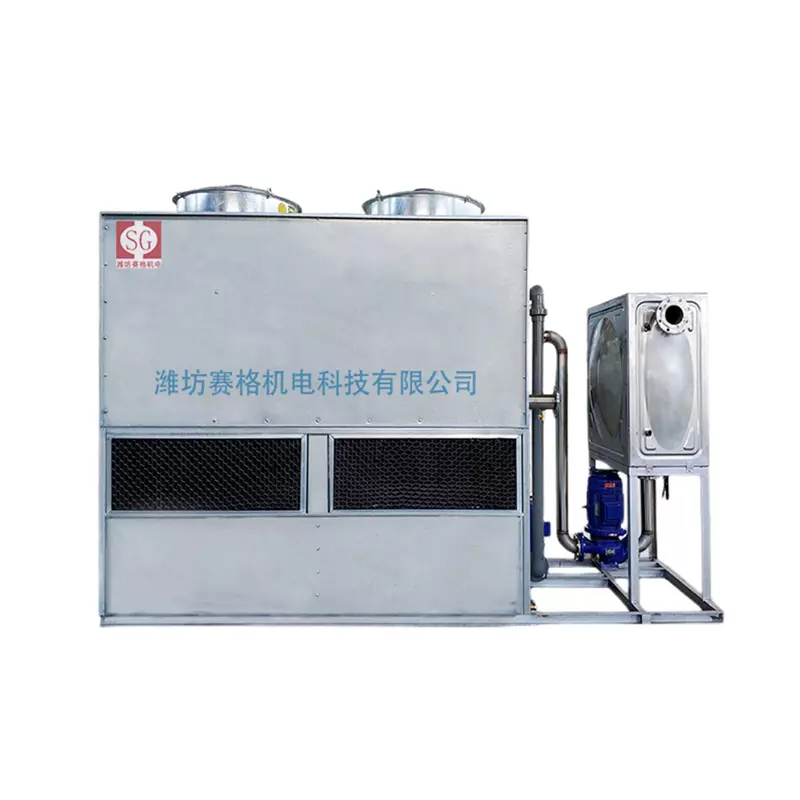

View DetailsClosed-loop water cooling equipment

50T, 60T, 80T are equipped with dual pumps. If there are more than one cooling path, please indicate in advance. It can be customized.

View DetailsNumerical Control Quenching Machine Tool

The CNC quenching machine tool series includes two types: vertical quenching machine tools and horizontal quenching machine tools.

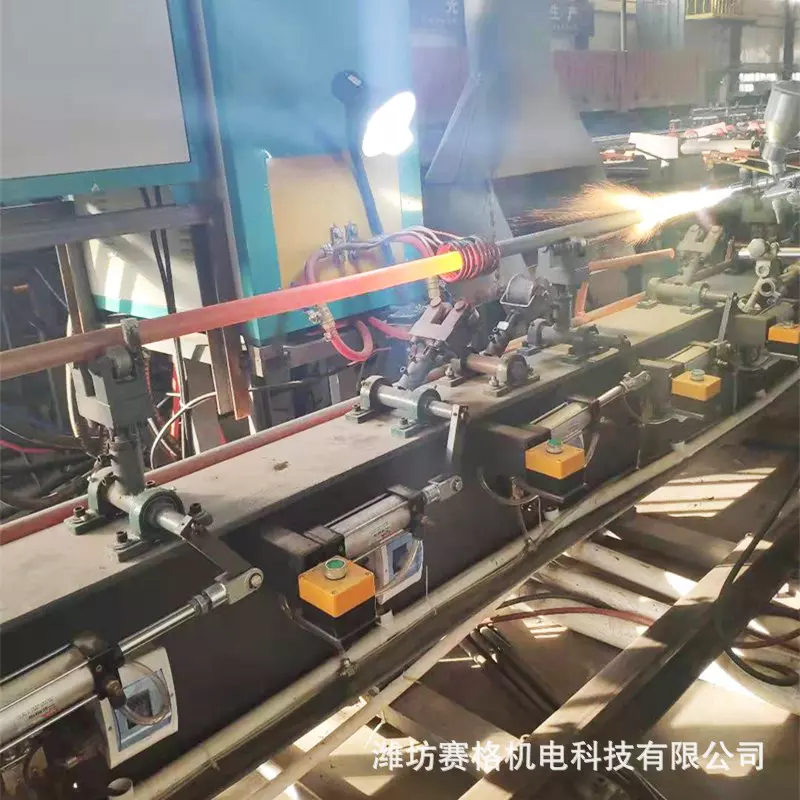

View DetailsOil pipe cleaning and refurbishment production line

This set of equipment is used to clean the inner and outer walls of the oil pipe, and includes straightening, cleaning, casing replacement, threading, pressure testing, flaw detection and other processes.

View DetailsProduction line for forged sucker rod heads

Applicable for the material rod transmission of solid sucker rods and the heating of the rod head before

View DetailsRod surface quenching production line

At present, many oil equipment manufacturers are still using electron tube high-frequency induction heating equipment or thyristor medium-frequency induction heating equipment to quench the surface of the sucker rod.

View DetailsPolished Rod Spray Welding Remelting Production Line

Before the operation of the solid rod spray welding production line, water and electricity must be supplied

View Details