Products

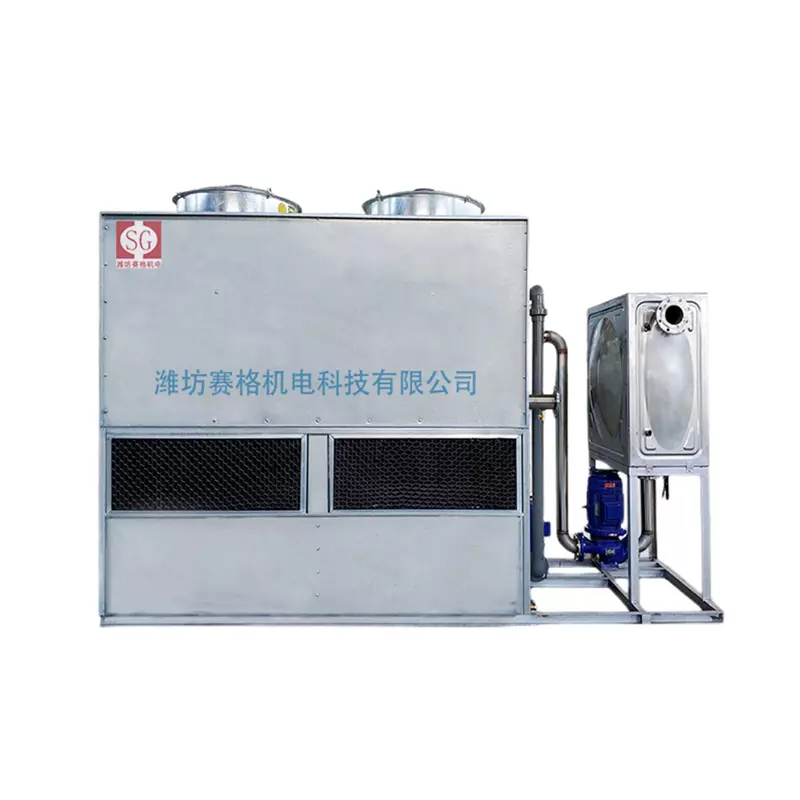

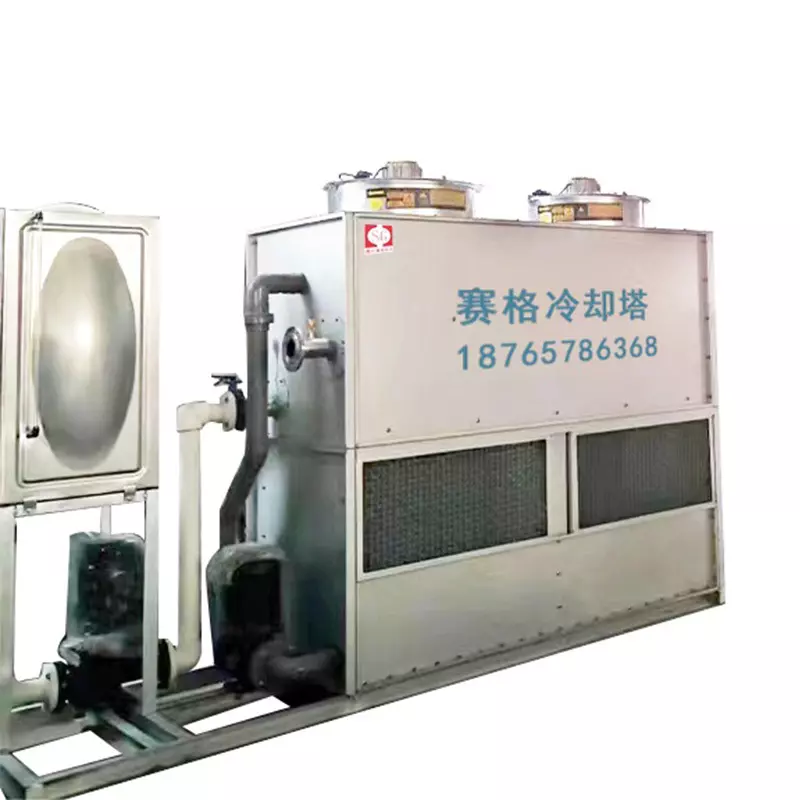

Closed-loop water cooling equipment

50T, 60T, 80T are equipped with dual pumps. If there are more than one cooling path, please indicate in advance. It can be customized.

Classification:

Closed water cooling equipment

Key words:

Closed-loop water cooling equipment

Product Description

Air cooling section: The working fluid (soft water or other liquid) circulates in the coils of a closed cooling tower, and the heat of the fluid is absorbed by the tube walls of the coils. The heat of the tube walls is then discharged outside the machine through the top fan.

Water cooling part: When the fluid temperature is too high (exceeding the set temperature), the spray system automatically starts, and the spray pump sprays water on the wet and hot pipe wall to form a water film, which absorbs a large amount of heat through evaporation (latent heat of evaporation). Part of the sprayed water turns into water vapor, which is carried away by the flowing air. The unevaporated water drops into the collection tank for the next cycle of use. The fluid in the coil is circulated in a closed manner, theoretically with no consumption. The consumption of spray water is only 0.1-0.2% of the unit flow rate.

Main Features

(1) The closed circulation of the circulating cooling medium ensures the purity of the medium without impurities entering;

(2) Soft water is used for water circulation, which does not scale or block pipelines;

(3) Small footprint, can be moved and placed as needed;

(4) Low energy consumption, simple and reliable operation.

1. Cooling pipe induced draft counterflow type

The heat dissipation of a closed cooling tower is determined by the air volume and the amount of evaporated water. When the fan power decreases (air volume decreases), it is necessary to increase the evaporation area (heat dissipation pipe area) to increase the amount of evaporated water. In order to lower the operating costs of customers, it is necessary to increase the cost and increase the evaporation area to reduce the power consumption of high-power fans, thereby reducing power consumption and achieving returns on customer interests and investment benefits.

2. T2 deacidification copper tube cooler with all international standards

The cooler for the closed cooling tower is made of internationally standard T2 deacidification copper tube, all of which are bare copper round tubes without fins to ensure its cooling effect.

3. Fan

The blades are made of aluminum alloy, and the motor is a three proof motor with an aluminum shell, which has low noise and high transmission efficiency.

4. Moisture proof sealed water pump

Adopting high-efficiency water pump, low water pressure, not easy to block, low loss, and extremely low power consumption; The pump body has a compact structure, small volume, beautiful appearance, easy installation, smooth operation, low noise, high component concentricity, no leakage, and easy maintenance.

5. Dehydrator

The main function of the dehydrator is to exhaust the water from the spray water and hot steam through the exhaust system; PVC high-efficiency dehydrator ensures efficient ventilation while keeping the flow rate of spray water extremely low, less than 0.2%.

6. Collecting tank

The main function of the water collection tank is to store spray water. It consists of a tank, a float valve, an inlet filter, a water replenishment port, a sewage outlet, etc. The inlet filter is made of 304 stainless steel material

7. Sink

The enclosed cooling tower is equipped with a water collection tank device, which has a large water collection capacity, a wide area, and good heat dissipation, fully meeting the technical requirements for spraying water.

8. Floating ball valve

Stainless steel float ball valve has a long service life, good water replenishment effect, and ensures the water storage capacity of the sink.

9. Water tank and auxiliary equipment

Made of 55% aluminum zinc plated plate, it has a beautiful appearance and a closed circulating cooling medium, but there is still a very small amount of loss.

10. Control system

It has automatic control, display, protection, alarm and other functions, with a beautiful appearance and a concise operation interface.

Pressure control system: The cooling tower is equipped with a pressure display at the inlet, and there is also a pressure display at the inlet of the equipment that needs to be cooled. The pressure drop can be read through the pressure difference to achieve effective cooling and ensure safe water flow.

Temperature control system: The cooling tower is equipped with temperature measurement at the inlet and outlet, displaying temperature and temperature alarms on the panel, and can adjust the inlet and outlet water temperature by controlling the spray switch through a digital temperature controller, so that the closed cooling tower can continuously and efficiently cool the equipment within the specified water temperature range.

Technical Parameter

| Model/Specification | Shell material | Cooling pipe material | Host size (mm) | Auxiliary machine size (mm) | Main pump (KW) | Spray pump (KW) | Caliber | ||

| 10T | 304 stainless steel | Aluminum zinc plated sheet | Copper tube | Stainless steel pipe | 2280*900*2150 | 2.2 | 1.5 | DN50 | |

| 20T | 3000*900*2150 | 4 | DN65 | ||||||

| 30T | 3000*900*2500 | 4 | |||||||

| 40T | 3000*1150*2500 | 5.5 | |||||||

| 50T | 2800*1150*2500 | 1000*1200*1800 | 5.5 | ||||||

| 60T | 2800*1150*2700 | 1000*1200*1800 | 7.5 | ||||||

| 80T | 2800*1430*2800 | 1000*1200*1800 | 7.5 | 2.2 | DN80 | ||||

| 100T | Custom | Custom | Custom | Custom | |||||

| 150T | |||||||||

| 200T | |||||||||

| 250T | |||||||||

| 300T | |||||||||

Note: 50T, 60T, 80T are equipped with dual pumps. If there are more than one cooling path, please indicate in advance. It can be customized.

Service Purpose

The pursuit of value is the starting point of our work, creating value is the driving force of our life, and realizing value is our constant pursuit! To provide customers with advanced automation products and technology, in accordance with the principle of customer first, mutual benefit, to provide perfect sales and technical services.

Customer Visits

Sincerely welcome all sectors to visit, inspect, and negotiate business. Our company will rely on scientific management, high team spirit, and the wisdom of all employees to take advantage of the booming development of Shandong and work together with all sectors of society to promote the progress and development of SEG automation control technology.

Customer Service

Qualification patent

Digging deep into customer resources is the foundation of our work, and cooperation and interaction are the process of our work; cost saving, profit maximization, quality service, and advancing with the times are the focus of our work, and win-win is the result of our pursuit

recommend products

Ultra-high frequency induction heating power supply equipment

Ultra high frequency induction heating equipment is widely used in fields such as metal processing

Ultrasonic induction heating equipment GCYP36

The ultrahigh frequency induction heating equipment uses IGBT modules

Ultrasonic induction heating equipment GCYP65

The ultrahigh frequency induction heating equipment uses IGBT modules

Ultrasonic series induction heating equipment

The ultra-audio induction heating equipment adopts IGBT module, which is energy-saving and power-saving: 30% power-saving compared with electronic tube type and 20% power-saving than controlled silicon intermediate frequency.

Welcome your message consultation

Our staff will contact you within 48 hours (working days), if you need other services, please call the service hotline