Products

MFP medium frequency induction heating equipment

Medium frequency induction heating equipment is widely used in heating occasions that require heat penetration.

Classification:

MFP intermediate frequency induction heating equipment

Key words:

MFP medium frequency induction heating equipment

Product Description

Medium frequency induction heating equipment is widely used in heating occasions that require heat penetration, such as: (1) heating and forging of standard parts; (2) melting of various metal materials; (3) heating and fitting of motor rotors; (4) heating and expanding the ends of steel pipes; (5) heat penetration for molds; (6) medium frequency quenching for shafts; (7) preheating or post-weld tempering of weld seams, etc.

Advantages of the equipment

1. Simple production operation, flexible material input and output, high degree of automation, can achieve online production.

2. Fast heating speed, high production efficiency, less oxidation and decarburization, saving material and forging die costs.

3. Uniform heating with minimal temperature difference between core and surface, high temperature control accuracy.

4. Complies with environmental protection requirements, low pollution, while also reducing workers' labor intensity.

Equipment characteristics

1. Fully solid-state IGBT frequency conversion and functional adjustment, soft switch resonance dual control and automatic frequency tracking technology ensure high reliability;

2. Ultra-small size saves customers 10 times the production space;

3. High efficiency and energy saving across the full power range with extremely high power factor and power supply efficiency;

4. Wide frequency automatic tracking adaptability from 1 to 20KHZ without on-site debugging;

5. Capable of continuous operation at full load for 24 hours;

6. Constant output voltage/constant output power control selection function;

7. Frequency, power, voltage, and current are all displayed.

Working principle

When the medium frequency current is transmitted from the medium frequency converter through capacitors via connecting busbars to the transformer, an alternating magnetic field is generated in the induction coil. The metal blank within this alternating magnetic field induces a current (eddy current), converting electrical energy into thermal energy to heat the surface of the blank.

Structural composition

The medium frequency quenching furnace body includes a compensation capacitor cabinet with internal compensation capacitors, cooling inlet/outlet paths, circuits etc.

A capacitor cabinet made from steel plates and profile steel is welded together with internal compensation capacitors installed; cooling inlet/outlet paths are provided; an output transformer is installed on top with a heating induction coil on its secondary side; both compensation capacitors and transformers use water cooling. RFM type water-cooled electric capacitor usage instructions are attached in Appendix A.

The cooling water circuit includes a water inlet distributor and a return water collector; both are welded from copper pipes with small nozzles welded on top for cooling water to reach the inlet distributor which cools the induction coil through it.Water-cooled guide rails, electric capacitors, capacitor busbars then concentrate back into the circulation pool through the return water collector.

The circuit part consists of two parts: one connects medium frequency power supply to capacitor busbars generally using power cables; for large powers >500KW, copper bars are recommended which need to be installed on-site according to actual conditions; second connects capacitor busbars to induction coils generally using water-cooled cables or square copper pipes which manufacturers usually connect beforehand so users typically do not need to operate unless replacing induction coils.

Connecting incoming lines

Connecting incoming lines refer to cables connecting transformers to medium frequency power supplies.

Cables connecting between medium frequency power supply and capacitor cabinet.The specifications for these cables refer to voltage levels (380V,660V) and currents passing through them.

Specific different cable or copper bar carrying capacities can be checked in electrical manuals or by consulting manufacturers.

Water cooling system

Medium frequency induction quenching equipment requires cooling water for high-power heating devices such as thyristors, smooth wave reactors, induction coils, electric capacitors etc. Currently there are two forms of water cooling systems available for users: one is closed-loop cooling water system detailed in closed-loop cooling system section; two is discharge-type cooling method using a pool with a pump.

Technical parameters

Model | Working Power Supply | Working Voltage Range (V) | Output Power (KW) | Oscillation Frequency (Hz) |

MFP100 | 3×380Vac50Hz | 500-530v | 100 | 1-15 KHz |

MFP160 | 3×380Vac50Hz | 500-530v | 160 | 1-15 KHz |

MFP200 | 3×380Vac50Hz | 500-530v | 200 | 1-15KHz |

MFP300 | 3×380Vac50Hz | 500-530v | 300 | 1-15KHz |

Service Purpose

The pursuit of value is the starting point of our work, creating value is the driving force of our life, and realizing value is our constant pursuit! To provide customers with advanced automation products and technology, in accordance with the principle of customer first, mutual benefit, to provide perfect sales and technical services.

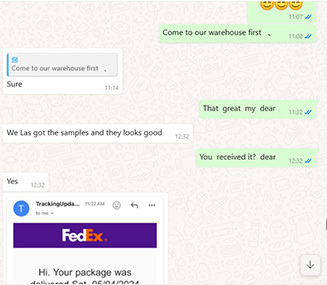

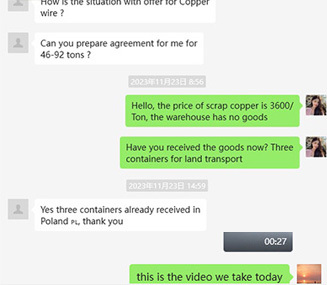

Customer Visits

Sincerely welcome all sectors to visit, inspect, and negotiate business. Our company will rely on scientific management, high team spirit, and the wisdom of all employees to take advantage of the booming development of Shandong and work together with all sectors of society to promote the progress and development of SEG automation control technology.

Customer Service

Qualification patent

Digging deep into customer resources is the foundation of our work, and cooperation and interaction are the process of our work; cost saving, profit maximization, quality service, and advancing with the times are the focus of our work, and win-win is the result of our pursuit

recommend products

Ultra-high frequency induction heating power supply equipment

Ultra high frequency induction heating equipment is widely used in fields such as metal processing

Ultrasonic induction heating equipment GCYP36

The ultrahigh frequency induction heating equipment uses IGBT modules

Ultrasonic induction heating equipment GCYP65

The ultrahigh frequency induction heating equipment uses IGBT modules

Ultrasonic series induction heating equipment

The ultra-audio induction heating equipment adopts IGBT module, which is energy-saving and power-saving: 30% power-saving compared with electronic tube type and 20% power-saving than controlled silicon intermediate frequency.

Welcome your message consultation

Our staff will contact you within 48 hours (working days), if you need other services, please call the service hotline